Assignment: For this final fabrication assignment, we were asked to build something with a motor. The main fabrication skill to focus on was mounting the motor. Any of the conceptual or interactive work was secondary to motor-mounting, but given that we were all going to have time to present to the class, it was important to me to think about the audience experience.

Stories and Inspiration:

Two anecdotes. First:

Back in 2013 I spent a month in Ladakh, a town in the Indian Himalayas. While there, I visited a number of monasteries. On of of those visits, I spoke with a monk who had just finished raking stones into a pattern. The courtyard we were standing in was windy and rocks were already shuffling out of place. I asked the monk about this practice of raking the rocks; if the rocks were going to be out of order within moments, why do it each morning?

The monk replied by calling my attention to the window out of the courtyard. The monastery stood upon a cliff, high up on a mountain jutting out into a valley. It was exposed to all of nature’s elements, including the wind that we were now feeling. “This mountain will be destroyed,” he said matter-of-factly, “and that is why it was built here. It serves as a daily reminder that even that which we hold most sacred will not last.”

Second:

I’ve been fermenting a lot of food and trying to learn about food cultures around the world. Although the specific pickling and preserving techniques vary wildly not only across countries but within them, the biological principles we use to ferment are similar. At its philosophical core, too, we’re doing something similar: we’re harnessing decay. We’re recognizing the impermanence of our food materials and seeing an opportunity to embrace change— to make something new of the old.

I wanted to reflect on these two anecdotes through this project and bring my classmates into this reflection with me.

Idea:

I told my classmates the story from the monastery and asked them to reflect on three questions:

1) What is something that feels permanent in your life

2) What is something that feels important now but you know will not be later

3) Make a prediction for 30 years into the future

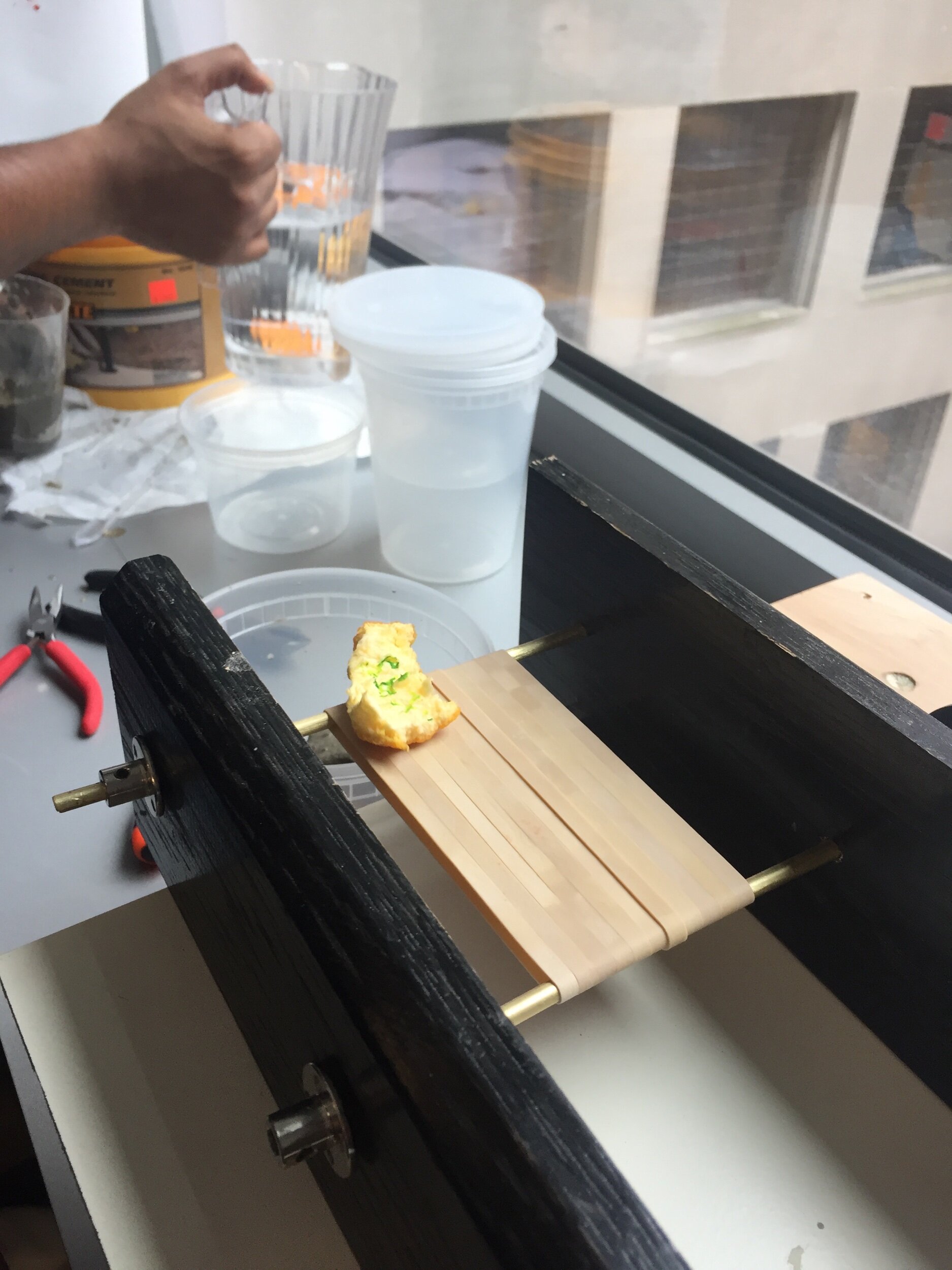

I then passed out pieces of orange peel and markers to my classmates and asked them to write at least one of their answers on those pieces. Then, they placed these pieces on a conveyor belt— the fabrication project— which dropped into a container. I poured layers of cement over the pieces of organic matter (I added some pieces of cheese and also passed out paper to write answers upon in addition to the orange peel.)

Some photos from the demo, then fabrication notes and reflections after the jump.

Fabrication: I cobbled together pieces from Brunos, Home Depot and (mostly) Jake and Noah — a million thanks to them! The conveyor belt used a motor with a 100 rpm gearbox, but 2000+ rpm motor — there was a lot of torque at the slow speed, which is useful for a conveyor belt. I built the frame and motor mount with scrap wood from the shop and wood screws to keep things in place. The belt itself was held together with some zinc-plated pipes and shaft couplers-like pieces to secure the pipes in place (this isn’t the right term; I’ll edit when I find the right one.) After testing with tape (taped to itself) and cardboard to no avail, I finally made the belt from a bunch of rubber bands. It actually proved to be quite effectively and looked nice to boot.

Improvements: I began this project the day before it was due, which was a nightmare. I knew what I wanted to build, but was waiting on parts for most of the week, and also just made the calculation that I needed to get other assignments done first and could get this one together in time for class. It led to a lot of running to the hardware store, a lot of shoddy craftsmanship, but ultimately a demo that I was happy with. I’d like to do this over again with better materials and more attention to the quality of fabrication; all of the screws should be flush, all of the holes for the zinc pipes big enough for good belt rotation, I should get the right sized pieces of wood (or something else the next time around) to make the whole setup more efficient.

For the demo, I’d like to experiment with different organic materials and different concrete molds. I may tweak the questions as well. Overall, I liked that my classmates seemed engaged and appreciated the opportunity for reflection; I think there’s a path to making this engaging for another audience.